1. Ethylene Glycol : EG

It has a freezing point lower than 0, so it can prevent the solidification of the solution. It is useful for cars in cold cities.It has a high boiling point to prevent overheating of engines and corrosion and also acts as a solvent for inhibitors and colors.

2. DI water

It works as a solvent of inhibitors and colors.

3. Additives

Inhibitors prevent rust and corrosion of metals. Anti-foaming: Controls the formation of foam during coolant filling and anti-corrosion.

Color : Separate coolant from oil and water to prevent mistakes or swallowing.

Golden Cruiser uses an anti-rust additive with excellent heat resistance and oxidation resistance. Therefore, it can maintain anti-rust and anti-corrosion performance for a long time.

Because Golden Cruiser uses high-quality ethylene glycol, it has a stable antifreeze effect and prevents freezing problems.

Coolant helps absorb heat from the engine. The circulation and impact of the outside wind while driving helps to reduce the temperature in the engine. Golden Cruiser has excellent cooling performance and protects the engine from overheating problems.

The combination of special additives prevents cavitation damage to the cylinder and water pump which is the main cause of engine damage. Golden Cruiser is effective in inhibiting cavitation and extends the service life of components in the cooling system.

*Cavitation is a phenomenon in which the pressure of the coolant changes from the flow or vibrates until the formation of air bubbles. The pressure generated by the impact of these bubbles damaged the cylinder and water pump. It is the main cause of engine damage

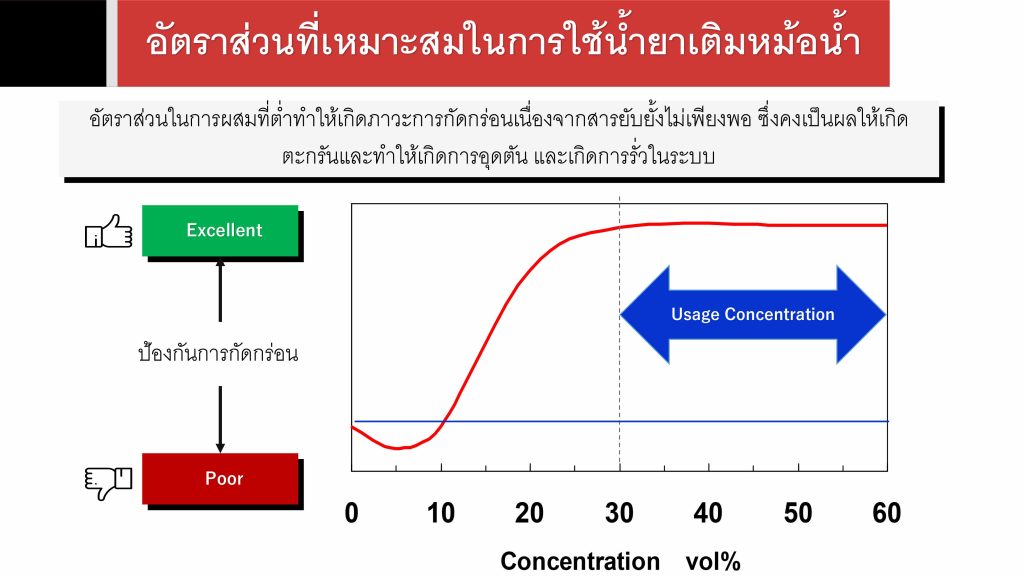

The proper ratio for engine coolant.

Let’s see the right ratio to use for radiator additives.

The low mixing ratio will cause corrosion due to insufficient inhibitors (Additive/inhibitor), which results in various scales and causes clogging. Including the occurrence of a leak in the system. From the graph showing the ratio of coolant from 0 to 60 percent, you will see that the efficiency in anti-corrosion is range between 30% – 60% concentrated.

More

As for Hino’s coolant At 50% concentration, it provides the most cost-effective corrosion protection because in changing the radiator coolant there may be residual water after the system is not fully flushed. We add the radiator coolant and mixed with water that remains in the system which decreases the concentration of coolant. So, for most effective protection is at 50% concentration, but when it comes to 60% concentration might be better or not? Better, of course, but the price will go up accordingly and may not need to be so concentrated. The result shows that the ratio of mixing the radiator is 30 – 50% the metal parts do not show signs of corrosion. Compared to the reduced ratio of the radiator, for example at 5%, it can be seen that there are traces of corrosion on the metal plates, so if we use the radiator at a ratio of less than 30%, it will reduce the properties of the radiator.

There is a metal corrosion test by cutting 6 types of workpieces together, which are examples of metal groups used as parts in the engine system 1, 2, 3, 4, 5 and 6 soaked in the radiator at a temperature of 88 degrees for 336 hours.